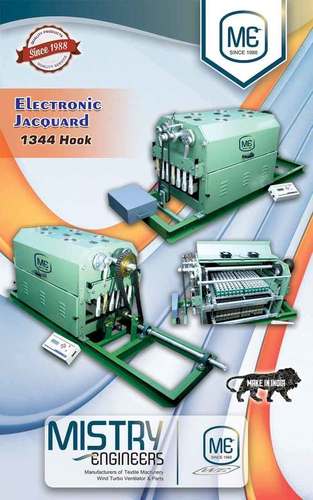

About Electronics Jacquard Machines

We are offering our customers a wide range of Electronic Jacquard machine.

Field of applications: be widely used in weaving of trademarks, tie, towels, table, clothing and other jacquard fabrics.

Suitable looms : with matured and adjustable shed design, to be workable with many types of imported high speed looms,

Advanced Control and VersatilityFeaturing a sophisticated microcontroller-based control system, this Jacquard machine adapts to the needs of different weaving mills. It supports both standard and custom sizes, making it compatible with various loom setups. Its versatile mounting and multiple thread compatibility enable seamless operation, enhancing production efficiency and fabric variety.

Durability and Precision EngineeringBuilt with premium materials and engineered for reliability, the machine offers a polished, corrosion-resistant surface and high hardness (45-55 HRC). Its precision components, including the Jacquard hook, ensure consistent, high-quality output. Designed for long service life, it withstands demanding industrial use while maintaining low maintenance requirements.

Simple Installation and High OutputThe machines top-mount design and customized options make installation straightforward. It is suitable for both new setups and retrofitting existing looms. Its high-speed capability (200-350 RPM) and high output capacity cater to large-scale, high-efficiency production environments, while maintaining low noise and optimal performance.

FAQs of Electronics Jacquard Machines:

Q: How does the microcontroller-based control system benefit the Jacquard machine?

A: The microcontroller-based control system provides precise and reliable control over weaving patterns and operations. This enhances efficiency, allows complex designs, and helps maintain consistency during high-speed production in industrial weaving mills.

Q: What types of Jacquard looms are compatible with this machine?

A: This Electronics Jacquard Machine is designed to be suitable for a wide range of Jacquard looms, thanks to its customizable size, hole configurations, and top-mount design. This ensures easy integration with both standard and specialized looms used in textile industries.

Q: When is the optimal time for installation and use of this Jacquard machine?

A: The machine is easy to install and can be integrated during new mill setups or when upgrading existing weaving lines. It operates efficiently within an operating temperature of 0 to 50C, making it suitable for most industrial conditions year-round.

Q: Where can I get servicing, support, or spare components for this machine in India?

A: As the machine is supplied by a broad network of dealers, distributors, exporters, fabricators, importers, manufacturers, producers, retailers, service providers, suppliers, traders, and wholesalers in India, comprehensive support and spare parts are readily available throughout the country.

Q: What is the process of customizing the machine to match specific loom requirements?

A: Customization involves specifying the required number of holes, machine dimensions (L*W*H), hook diameter, and thread compatibility during the ordering process. The manufacturer configures the machine based on these parameters to ensure seamless integration with your weaving loom.

Q: How is the machine maintained, and what is its expected service life?

A: The polished, corrosion-resistant finish and robust construction minimize maintenance needs. Routine cleaning and periodic inspection of componentsespecially the Jacquard hooksare recommended. The durable materials and precision engineering provide a long service life, even under continuous, high-speed operation.

Q: What are the main benefits of using this Electronics Jacquard Machine in industrial weaving?

A: Key advantages include high-speed performance (up to 350 RPM), high output capacity, low noise levels, multiple thread compatibility, and long-lasting durability. These features contribute to increased productivity, lower operating costs, and more diverse weaving possibilities for mills.